A metal core printed circuit board is a specialized PCB designed with a metal base material to improve heat dissipation and overall performance. Unlike traditional FR4 boards, which use fiberglass-reinforced epoxy, metal core PCBs integrate a conductive metal—commonly aluminum, copper, or a mixture—beneath the dielectric and copper layers. This design allows them to efficiently transfer heat away from critical components, making them ideal for applications where high power and thermal management are essential. Industries such as LED lighting, automotive, power electronics, and industrial machinery rely heavily on metal core PCBs for their durability and thermal efficiency.

Structure of a Metal Core Printed Circuit Board

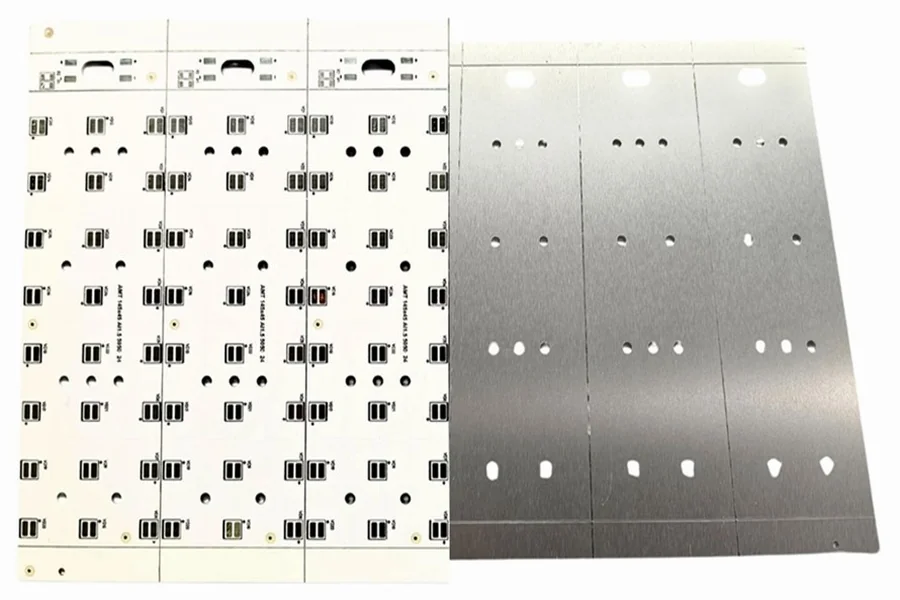

A typical metal core printed circuit board has three main layers: the metal substrate, the dielectric layer, and the copper circuit layer.

- Metal substrate: Usually aluminum or copper, it acts as the primary heat sink.

- Dielectric layer: A thermally conductive but electrically insulating layer that separates the copper traces from the metal base while enabling efficient heat transfer.

- Copper layer: Contains the etched circuitry that connects and powers the components.

This structure is specifically designed to manage higher temperatures without compromising the board’s electrical performance or mechanical stability.

Materials Used in Metal Core Printed Circuit Board

Material selection is crucial for achieving the desired performance in a metal core printed circuit board. Aluminum is the most common choice for its lightweight, cost-effectiveness, and good thermal conductivity. Copper, while more expensive, offers superior heat transfer capabilities and mechanical strength. The dielectric layer is typically made from thermally conductive epoxy or ceramic-filled polymer, with thermal conductivity ratings ranging from 1 W/mK to over 8 W/mK, depending on the application’s demands.

Advantages of Metal Core Printed Circuit Board

The main advantage of a metal core printed circuit board is its exceptional heat dissipation capability. This feature allows high-power devices to operate efficiently without overheating. Additionally, metal core PCBs offer:

- Improved reliability: Reduced thermal stress increases component lifespan.

- Mechanical strength: The metal substrate provides rigidity, making them suitable for high-vibration environments.

- Dimensional stability: Minimal expansion and contraction with temperature changes.

- High thermal conductivity: Enhances performance in power-intensive applications.

These benefits make metal core PCBs an excellent choice for applications like high-brightness LED modules, motor controllers, and RF power amplifiers.

Applications of Metal Core Printed Circuit Board

Metal core printed circuit boards are widely used in industries where heat is a major concern. LED lighting systems benefit greatly from their heat dissipation properties, which help maintain brightness and color stability over time. Automotive applications use them in headlights, brake lights, and engine control systems. In power electronics, they are found in power converters, inverters, and industrial drives. The telecommunications sector also utilizes them in high-frequency and high-power devices that require stable thermal performance.

Manufacturing Process of Metal Core Printed Circuit Board

The production of a metal core printed circuit board involves specialized processes to handle the metal base material. After cutting and preparing the substrate, the dielectric layer is laminated onto the metal. A copper foil is then applied on top, and the circuit pattern is etched using standard PCB manufacturing techniques. Drilling and plating vias require precision to avoid damaging the dielectric or shorting to the metal substrate. Finally, solder mask and surface finishes such as HASL, ENIG, or OSP are applied to protect the copper and enhance solderability.

Challenges in Metal Core Printed Circuit Board Fabrication

While metal core PCBs offer numerous advantages, their production comes with unique challenges. Drilling through metal requires specialized equipment and tooling, which can increase manufacturing costs. Thermal expansion differences between the copper and the metal base must be carefully managed to prevent delamination or cracking. Moreover, repairs and rework on metal core PCBs are more difficult compared to traditional FR4 boards, requiring skilled technicians and proper handling.

Choosing the Right Partner for Metal Core Printed Circuit Board Production

When developing high-power or thermally demanding products, partnering with an experienced Metal Core PCB manufacturer is essential. An expert manufacturer can help with material selection, thermal design optimization, and precision fabrication to ensure your board meets exact performance requirements. Working with the right partner not only guarantees consistent quality but also helps reduce lead times and overall production costs, giving your product a competitive edge in the market.