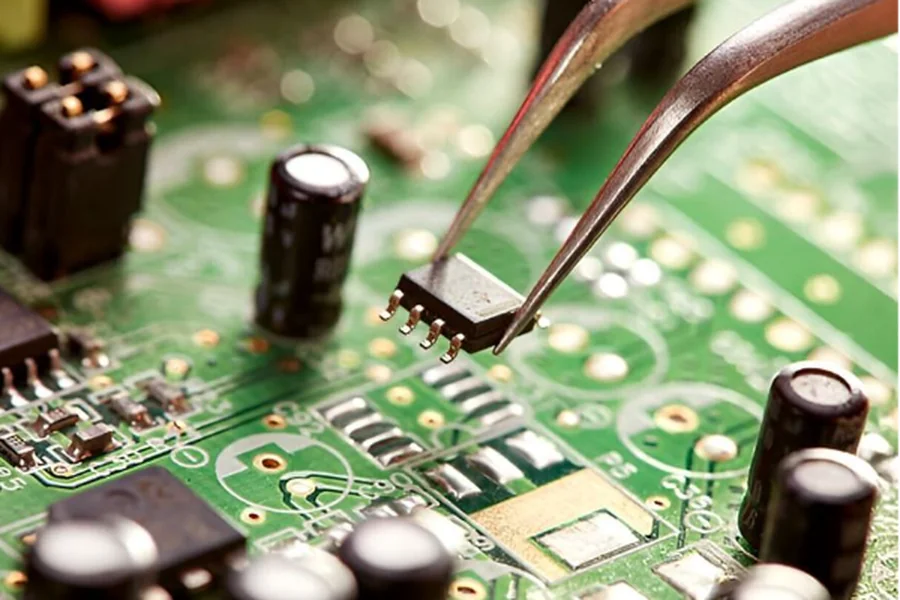

Flex PCB assembly is the process of mounting electronic components onto flexible printed circuit boards, allowing the final circuit to bend, twist, or fold without damaging the electronic connections. This technology is essential in modern electronics where compact, lightweight, and highly durable performance is required. Flex circuits are made from flexible materials such as polyimide, which provide remarkable mechanical endurance and thermal stability. Because of these qualities, flex PCB assembly is widely used in applications that demand both electrical reliability and physical adaptability, creating new possibilities for innovative product designs.

Why Flex PCB Assembly Matters in Modern Electronics

Flex PCB assembly plays a vital role in the evolution of compact and portable devices. As electronics become smaller and more multifunctional, traditional rigid boards cannot meet the spatial and mechanical requirements. Flex circuits bridge this gap by providing electrical continuity in areas where rigid PCBs cannot fit. In wearable devices, foldable gadgets, medical sensors, automotive displays, and aerospace systems, flex PCB assembly makes it possible to create lightweight, high-performance solutions that can withstand repetitive bending and complex geometries.

Flexibility Without Compromising Performance

What makes flex PCB assembly so powerful is its ability to combine physical flexibility with high electrical performance. Flexible substrates maintain conductivity even under stress, and because the material can bend, designers can route circuits through tight spaces, corners, or moving parts without risking disconnection. This flexibility also reduces the need for connectors, joints, and wires, resulting in better signal integrity and fewer mechanical failure points. The result is a more durable, reliable, and efficient device that performs consistently in real-world conditions.

Materials Used in Flex PCB Assembly

The materials used in flex PCB assembly significantly influence durability, bendability, and thermal resistance. Polyimide is the primary substrate because of its excellent flexibility, heat tolerance, and chemical resistance. Copper foil serves as the conductive layer and can be applied in rolled annealed or electro-deposited form depending on the required flexibility level. Adhesives and coverlays help protect the copper traces while maintaining the board’s ability to flex. Because these materials directly impact long-term performance, choosing high-quality materials is essential for achieving stable and reliable flex PCB assembly results.

The Importance of Rolled Annealed (RA) Copper

One of the most crucial material decisions in flex PCB assembly is selecting the right copper type. Rolled Annealed copper is preferred when the circuit needs to endure repeated bending, making it ideal for wearable electronics, hinges in foldable devices, and robotics. RA copper stretches without cracking, which ensures the circuit can flex tens of thousands of times without failure. This capability is essential in applications that involve dynamic movement.

The Flex PCB Assembly Process

The process of flex PCB assembly requires extreme precision because the substrate is thinner and more delicate than rigid boards. It begins with preparing the flexible PCB layers, including copper etching, coverlay application, and via formation. Once the layers are ready, surface-mount technology machines place components onto the flexible board. The soldering stage typically uses reflow soldering with carefully monitored temperature profiles to avoid damaging the flexible substrate. After component mounting, the board goes through inspection processes such as AOI and X-ray scanning to ensure proper solder joints and correct component alignment.

Challenges in the Assembly Process

Flex PCB assembly presents unique challenges. The thin and pliable substrate requires specialized handling to prevent bending or stretching during assembly. Excessive heat during reflow can cause warping, so temperature profiles must be optimized with precision. Component placement also demands advanced machinery because traditional pick-and-place systems may apply too much pressure. These challenges make experience and specialized equipment essential for achieving consistently reliable results.

Applications of Flex PCB Assembly

Flex PCB assembly is used across a wide range of industries where size constraints, movement, and environmental resistance are key considerations. In consumer electronics, flex circuits are found in foldable phones, smartwatches, cameras, and Bluetooth devices. The medical industry depends on flex PCB assembly for equipment such as wearable health monitors, imaging systems, and implantable devices, where both flexibility and reliability are essential. Automotive manufacturers use flex PCBs for infotainment systems, dashboard displays, and sensors where durability in high-temperature environments is critical. Aerospace applications rely on them for communication modules and control units, where vibration resistance is vital.

Growing Demand in Next-Generation Devices

As technology shifts toward miniaturization and multifunctional capabilities, flex PCB assembly will continue to play a crucial role. With the rise of flexible displays, stretchable electronics, and smart wearable ecosystems, demand for flexible circuits is growing rapidly. Innovations in materials, adhesives, and multilayer flex designs are expanding the possibilities for even more compact and complex devices.

Benefits of Flex PCB Assembly

Flex PCB assembly offers numerous advantages that cannot be achieved with rigid boards alone. A major benefit is improved reliability, as flexible circuits eliminate many mechanical connections, reducing the risk of solder cracks or loose connectors. Their lightweight design makes them ideal for compact and portable devices. Flexibility allows them to integrate seamlessly into tight or unconventional spaces, improving overall device aesthetics and functionality. Their resistance to vibration and mechanical stress makes them suitable for demanding environments such as automotive and aerospace applications. Additionally, the capability to create both single-layer and multi-layer flex circuits provides designers with greater freedom in creating advanced electronic systems.

Final Thoughts

Flex PCB assembly is a critical technology enabling today’s most innovative electronic products. Its ability to combine durability, flexibility, and high electrical performance makes it essential for industries ranging from consumer electronics to aerospace and medical technology. As devices continue to shrink and require more complex functionality, flex PCB assembly will remain a key driver behind modern design and engineering. For companies seeking dependable and cost-effective production, partnering with a trusted provider of PCB assembly in China is an excellent way to secure high-quality flex PCB solutions that meet the demands of advanced applications.